Post Time: 2023-09-21 08:55:18

The safety protection level of electrical equipment is one of the most important indicators for evaluating the protection function of electrical equipment, and IP65 protection level is one of the common test standards.

The IP65 protection rating test is a rigorous physical protection test for electrical equipment to assess its ability to adapt to different environments. Where IP stands for International Protection Rating, and the numbers 6 and 5 represent the ability of the electrical equipment to withstand dust and water respectively, IP65 rating means that the electrical equipment is fully dustproof and resistant to low pressure jets of water. This is particularly important for electrical equipment used outdoors, in industrial environments or other wet and dusty locations.

| Protection class | Protection | Description | Test Method |

| IP65 housing | Able to protect against water jets | Water sprayed from any direction onto the housing by a nozzle (6.3 mm) must not have a harmful effect. | Test time: at least 15 minutes |

| Water volume: 12.5 liters per minute | |||

| Pressure: 30kPa at a distance of 3m | |||

| IP66 housing | Resistant to powerful water jets | Water sprayed onto the casing by a powerful jet (12.5 mm nozzle) from any direction must not have a harmful effect. | Test time: at least 3 minutes |

| Water volume: 100 liters per minute | |||

| Pressure: 100kPa at a distance of 3m | |||

| IP67 housing | Protected against submersion up to 1m | When the casing is diffused into water (immersed to a depth of up to 1 m) under specified conditions of pressure and time, no harmful quantities of water shall be introduced | Test duration:30 minutes |

| Submergence depth of at least 1M measured at the bottom of the device and at least 15cm measured at the top by Daly |

In the IP65 rating test, the level of protection of electrical equipment is assessed from a number of perspectives:

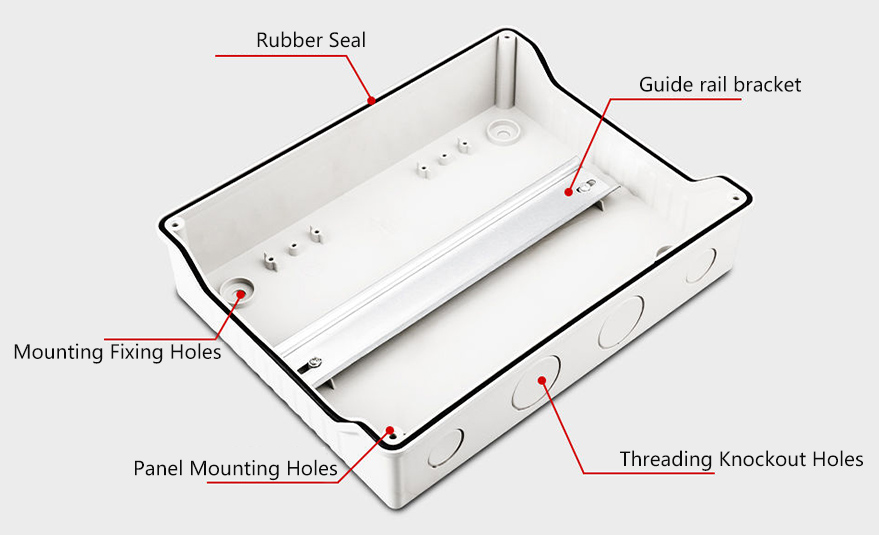

Enclosure sealing test: A jet test using a high-pressure accelerated stream of water is used to ensure that the enclosure of the electrical equipment is sealed to avoid moisture penetration into the equipment.

Fastening of fixings and connectors: The fastening of fixings and connectors is examined to ensure that the level of protection of the electrical equipment is not reduced due to loosening of the fixings in the course of use.

Dust protection test: A spray test using fine dust particles to assess the dust protection capability of the equipment to ensure that its internal components are not eroded by dust.

Waterproofing: Electrical equipment is sprayed with water to assess its ability to block water flow and to ensure that it can withstand harsh and wet environments.

SUDEBOX is waterproof in all aspects and strictly tested for your satisfaction:

tel

+13968715879